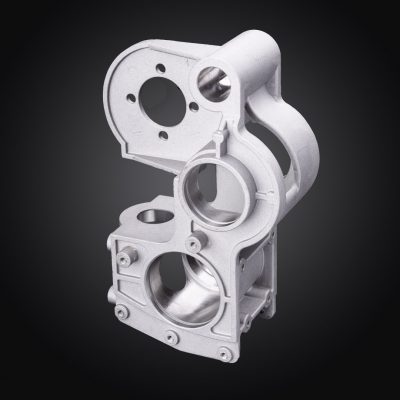

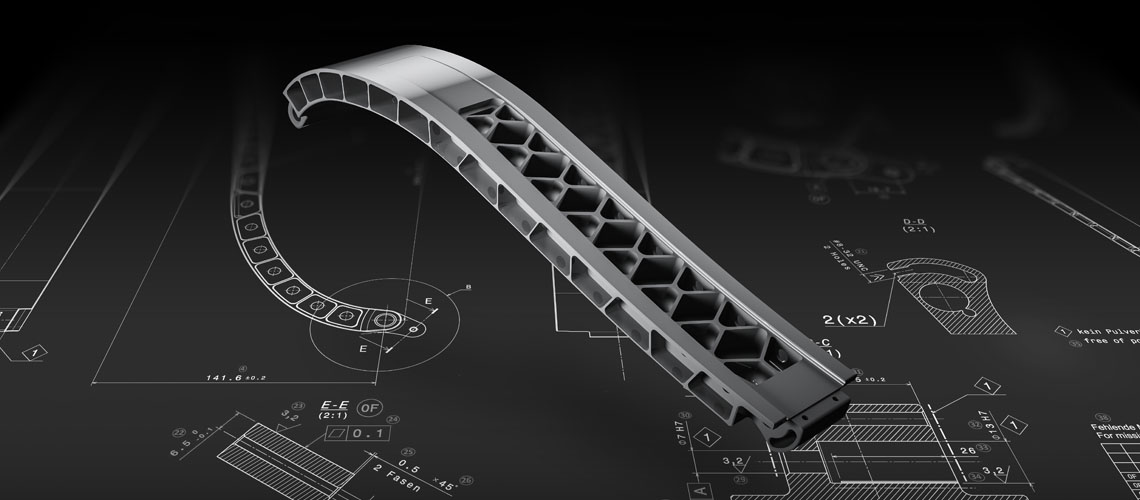

mobilverde technologies GmbH offers a wide range of services that goes far beyond the standard die casting procedure. Our aim is to work in partnership with you, so we can realise the optimum solution for your requirements and wishes, all from the one source.

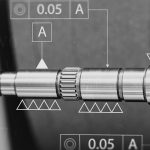

As a long-standing manufacturer of ready-to-assemble die cast parts and components with tolerance standards to ±0.05mm, we are able to guarantee optimum results and at the same time cost-effective complete solutions in all die casting processes, for many different application areas.