mobilverde is your supplier of high speed progressive and precision metal stamping solutions, and custom stamping technology solutions. Working in partnership with our external production facilities, we specialise in the mass production of highly precise, complex metal parts. Our experienced team can help optimise your design’s producibility, in order to lower your overall costs and meet the challenges that mass production of your individual component design may present. This is how we ensure your specific requirements are fulfilled according to your stipulations, and that you receive the stamping parts that you require.

Your system partner for stamping technology. Flexible. Precise. High quality.

Some examples of our stamped parts

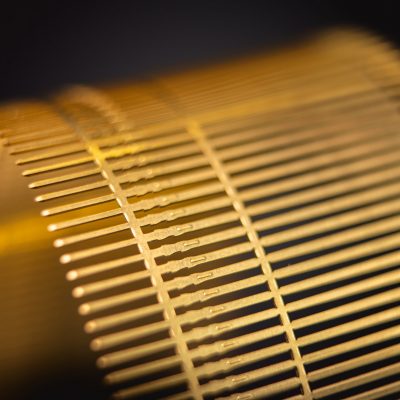

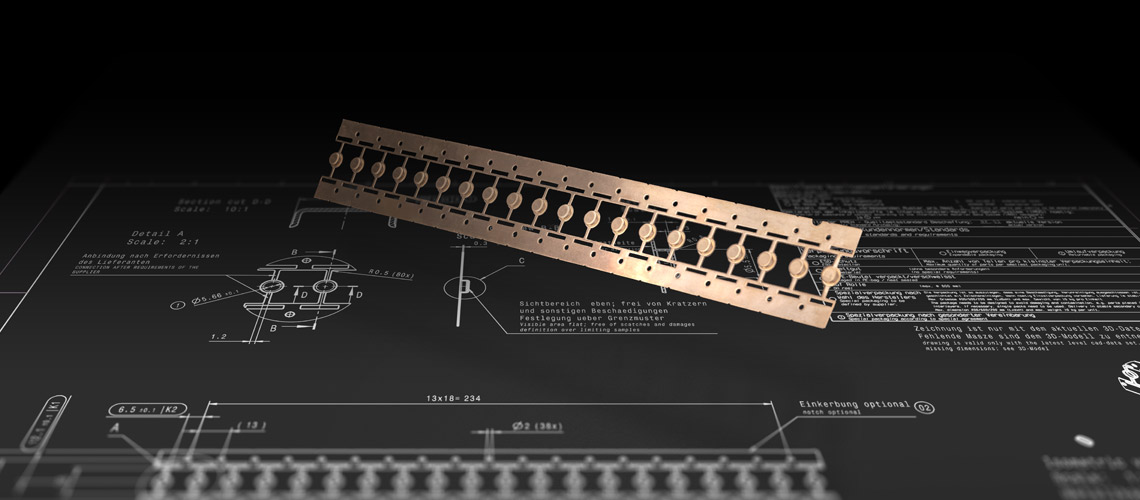

Stamped strip: cover for temperature sensor

| Material | Cu-ETP [DIN 1787 : E-Cu58] |

| Dimensions | 257 mm x 34 mm |

| Weight | 0,12 g |

| Production technology | Stamping |

| Tolerance | ± 0,05 mm [DIN-ISO 2768 – m] |

| Surface treatment | – |

| Application area | Cover for temperature sensor |

You can depend on us: our quality control system

We work together with leading OEMs and tier 1 suppliers, so that our many years’ experience can meet your demanding requirements. Thanks to a full quality traceability system and a strict quality control system, mobilverde is able to offer you high quality, highly efficient products and services.

Stamping technology: additional services

In order to satisfy the various requirements made of the components, mobilverde also offers value-added services such as: reel-to-reel electroplating, heat treatment, deburring, laser etching, welding and many more procedures, which we use to realise a wealth of products for globally active companies.

Make or buy

Has a make or buy analysis suggested to you that manufacturing your own stamped parts should no longer form part of your core business? Upon consultation, we would be pleased to inspect your tools on your premises, and work with you to plan a possible relocation. And in the event of capacity peaks and production bottlenecks, we would also be delighted to help you realise your manufacturing orders at short notice. Simply contact us. We thank you for your interest in our services.

Specifications, range and services: Stamping technology

- Reel-to-reel stamping

- Progressive stamping

- Deep-drawn stamping

- Metal terminal stamping

- Micro-metal stamping

- Sheet metal stamping

- 30 sets of high speed stamping machines with electronic sensors, in order to maintain reliable high speed stamping production while minimising downtime

- Tonnages of 30–160 tonnes, with stamping speeds of 60 to 1500 strokes per minute

- The sheet metal materials include: brass, phosphor bronze, beryllium copper, stainless steel, cold-rolled steel, aluminium and customer-specific special materials

- The sheet metal materials’ thicknesses range from 0.04–3.2mm. Feed hole: φ0.08mm, dimensional tolerance within +/-0.007mm.

- Stainless steel

- Aluminium

- Nickel silver

- Brass

- Copper

- Spring steel

- Small metal parts

- Deep-drawn parts

- Rivet elements

- Contact pins

- Contact clips

- Spring clips

- Shielding housing

- and many more

- Connectors

- Relays

- Sensors

- New energy batteries

- IC lead frames

- Telecommunications

- Solar and photovoltaics

- Medical electronics

- Tact switches

- Cable trees in cars

- and many more

Related processes

Enquire about our services now

With many years’ experience in stamping technology, mobilverde offers you lots of tailor-made metalworking services and custom solutions for your business. Simply get in touch with us!