mobilverde offers plastic injection molding solutions for various sectors, all from one source, spanning plastic mold making right up to the production of precision injection molded parts. As an expert in the field of injection molding, we have set ourselves the objective of offering high quality plastic injection molded parts in all common thermoplastic materials, and efficient quality services for the automobile, domestic appliances and electronics industries, as well as for general industrial OEM applications.

Precision, quality and innovation in the field of plastic injection molding

Some examples of our plastic injection molding

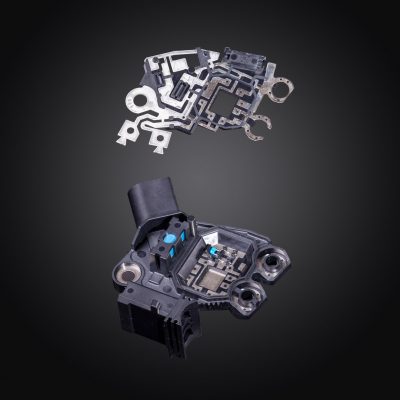

Regulating unit – automotive plastic components with integrated lead frames

- Polyphenylene sulphide PPS + 65% GF

- A definition of overmolding: A previously manufactured injection molded part, the so-called pre-molded part, is overmolded as part of an additional process.

- Plastic injection molded parts with metal inserts, stamped or turned, coated or bare conductors, semiconductor components

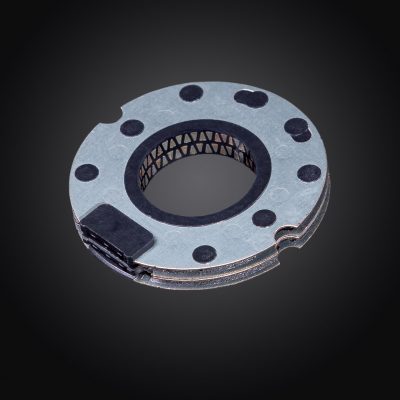

Sensor – automotive plastic components with integrated inserts and connection pins

- Polyamide PA 66 + 33% GF

- Versatile, precise and cost-effective: The overmolding process is one of the most commonly occurring processes in the plastics industry, enabling components and assemblies to be manufactured quickly and economically.

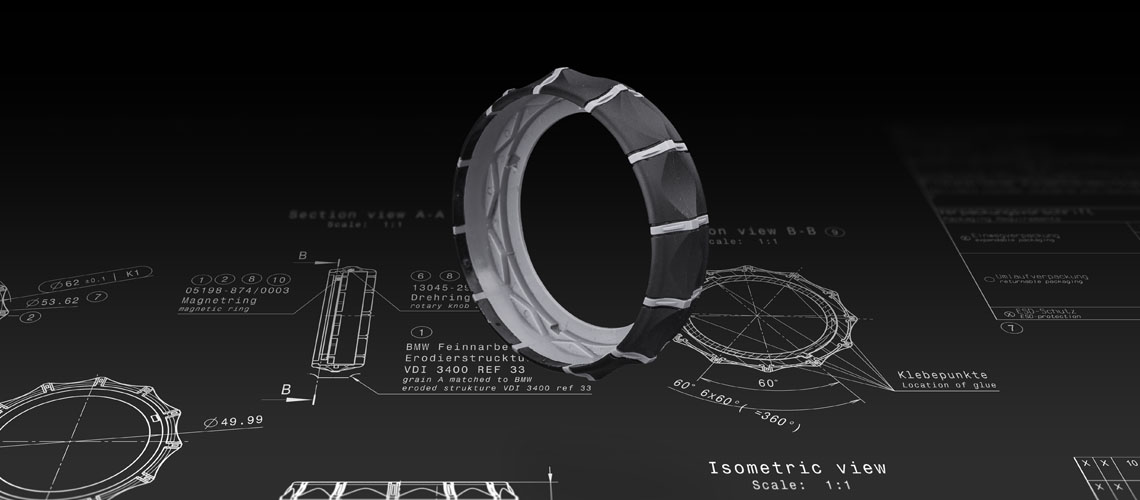

MMI rotating ring

| Material | PA6 (GF reinforced), Desmopan |

| Dimensions | 62mm diameter x 15.5mm height |

| Weight | 9 g |

| Manufacturing technology | 2-component plastic injection molding |

| Tolerance | ± 0,03 mm |

| Surface treatment | – |

| Application area | Rotating ring on motorbike handlebars |

Precise insert molds

Insert molds combine multiple materials and components into a single product. In this procedure, technical plastics or rubbers can be used with metallic materials, which provide strength and conductivity. You can be sure that mobilverde manufactures precise insert molds that meet your requirements:

- If you have a 3D model of your component, we make the mold exactly to your specifications.

- However, if you do not have a 3D model, we would be pleased to help you develop and produce exact, precise, error-free molds and components.

DFM and mold flow analyses

We use various analysis methods as part of our process optimisation. For example, DFM analysis, whose value lies in concentrating on the search for practical solutions to project hindrances that could jeopardise successful outcomes. The DFM analysis defines opportunities for reducing costs, improving producibility and accelerating the market launch. Mold flow analysis is another procedure. This tool analysis involves assessing, reworking and validating a tool, in order to ensure that it can correctly produce a plastic component at the very first attempt.

We manufacture for you as efficiently as possible

Has a make or buy analysis suggested to you that manufacturing your own plastic injection molded parts should no longer form part of your core business? Upon consultation, we would be pleased to inspect your tools on your premises, and work with you to plan a possible relocation of your production. And in the event of capacity bottlenecks and production peaks, we would also be delighted to help you realise your manufacturing orders at short notice. Simply contact us. We thank you for your interest in our services.

Specifications, range and services: Plastic injection molding

- Injection molding machines from 350 to 2000 KN clamping force

- Molded parts with weights from 0.01–400g

- Single and multi-component injection molding

- Lead frame and insert molding/overmolding [one stop-solution: stamping, electroplating and plastic injection molded parts]

- Micro molding/micro injection – tolerance range: to +/- 0.003mm

- Electronic components – tolerance range: to +/- 0.005mm

- Gas-assisted injection molding

- PEEK, PPS, PPE, PPA, PPO, PBT, PEI, PES, PET, PSU, PVC, PC, ABS, PE, PP, PS, PU, LCP, POM, nylon PA, PA6, PA66, PA6T, PA9T, TPE, TPR, TPU, TPV and more

Thanks to a full quality traceability system and a strict quality control system, mobilverde is able to offer customers high quality, highly efficient products and services.

- APQP (Advanced Product Quality Planning)

- QIP (Quality Inspection Plan)

- PFMEA (Process Failure Mode Effects Analysis)

- PPAP (Production Part Approval Process] Checklist

- MSA (Measurement system analysis)

- SPC (Statistical Process Control)

- GR&R (Gauge Repeatability and Reproducibility)

- ISO certification for suppliers

- 6S (5S + safety)

- Stamping

- Reel-to-reel electroplating

- Advice on plastic components

- Worldwide delivery capability

Related processes

Request your quotation

mobilverde offers you lots of tailor-made services and custom solutions for your business. Simply get in touch with us! We look forward to hearing from you.